|

Every few years, I

present a fresh solution for a Series 2 reversed alternator swap. This

is the latest and greatest. This alternator was selected because it shouldn't

be too hard to adapt to S1 4.2 or S3 applications, as well as S2. This

conversion can be accomplished for about a hundred bucks, and requires

only light fabrication with simple tools.

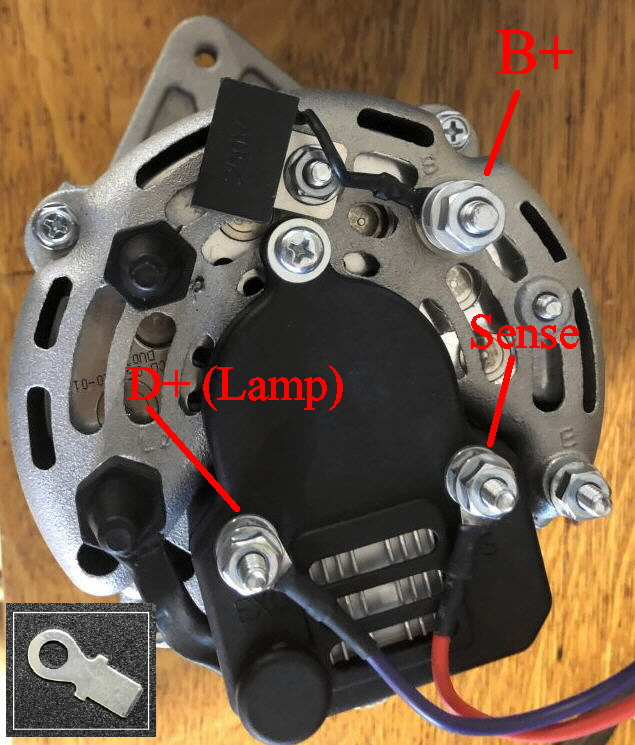

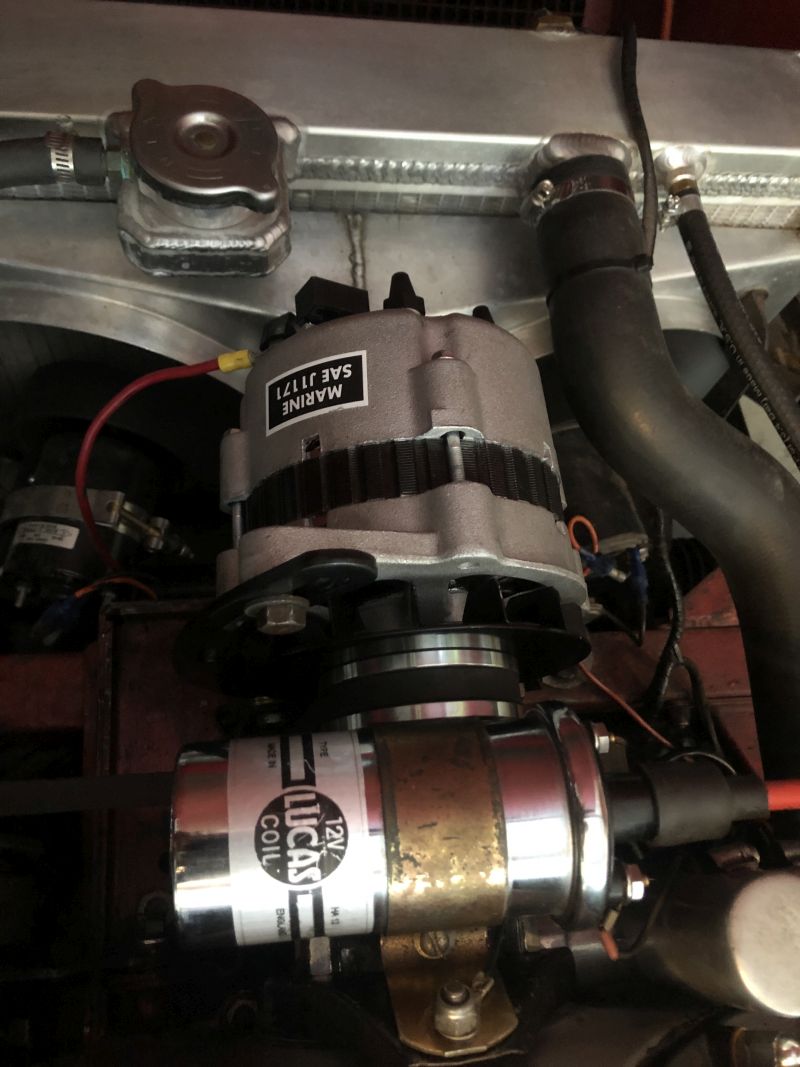

The alternator I selected for this role is commonly used on Mercury Marine stern drives. There are a couple of similar parts, PN 805884T or 807653 seem most applicable. While these may not be familiar in the automotive world, they are available from marine dealers, or buy them cheaply on EBay or Amazon. What makes this alternator interesting? First, it's a simple internally regulated alternator, so many components can be eliminated. It has a single foot mounting, like the first generation of 11AC alternators. It comes with a pulley and fan, and the fan is omnidirectional so it will function in either forward and reverse mount applications. It has a 5" frame, and the compact size makes it easier to squeeze into tight spaces. Output is typically 65 amps, which is adequate for all stock E-Type applications, including later A/C equipped models. It's regulated to produce 14.7V, which is ideal for AGM batteries. Final bonus, this alternator is SAE J1171 compliant, which means it's safe for sealed engine compartments. A tour of the alternator:

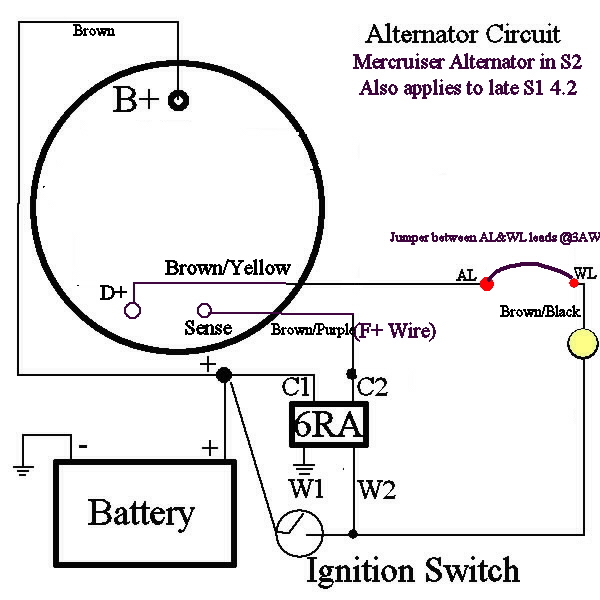

Installation on a Series 2 I installed this alternator

on my S2 mule using a very simple wiring plan. Since it's self regulating,

the 3AW and 4TR can be eliminated. The internal regulator is bootstrapped

by current flowing through the indicator light. Once the alternator begins

charging, the light goes out. Wiring is very straightforward.

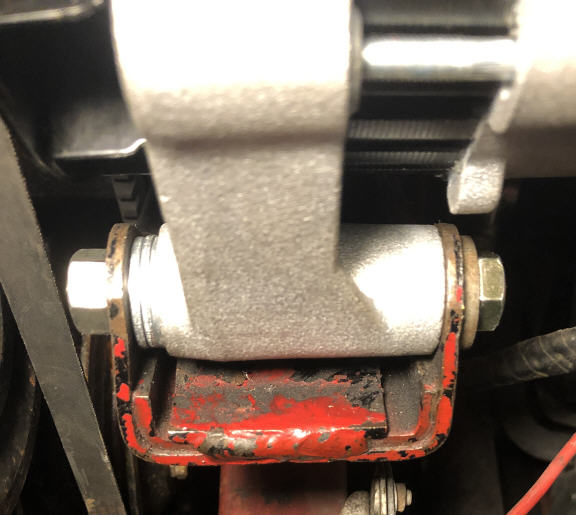

The physical installation

of the alternator is straightforward, although some light fabrication is

needed to make an adjustment arm. These mods apply to an early Series 2,

with the L shaped reverse mount bracket. Later models will require specific

tweaks not covered by this faq. The single foot will drop right into the

support bracket, with about 1/4" free motion front/back. The alternator

should be located forward to allow pulley clearance, but this may vary

from car to car. Use washers as needed for spacing, A tensioning arm was

fabricated from a Chevrolet bracket. That's really all there is to it.

Some photos:

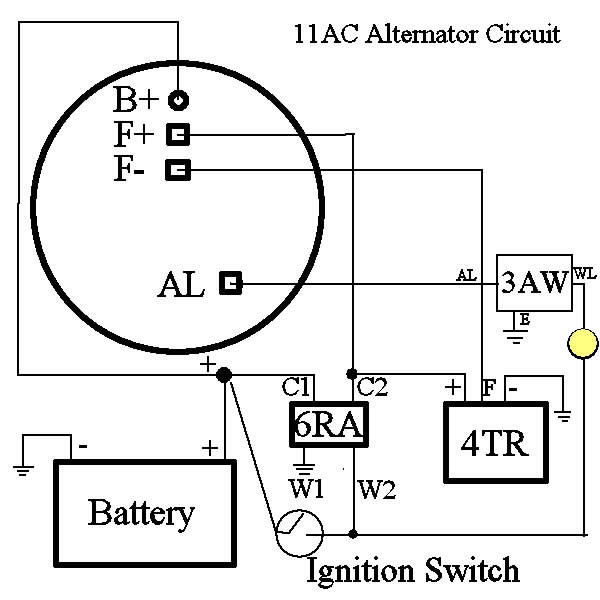

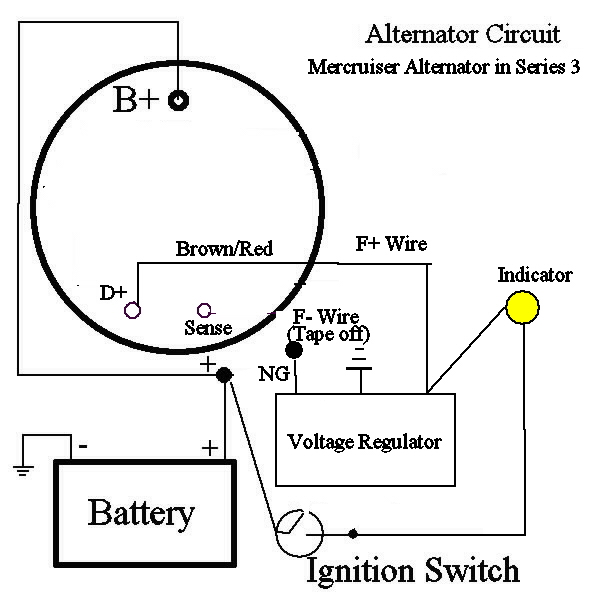

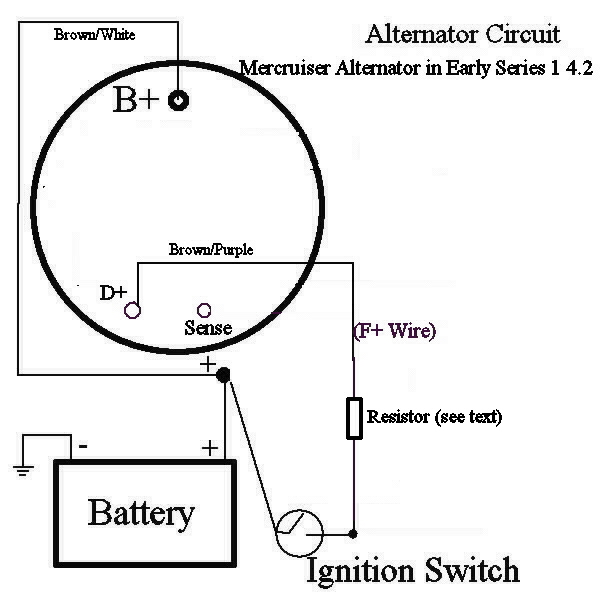

Installation on other models I'll document other

installations as they come up, but for now, here are the wiring diagrams

for each E-Type generation. Note that for all models except those with

3AW, all the wiring connections are made at the alternator, no new wiring

needed. The conversion time for any car should be no more than two hours.

Copyright © 2022 CoolCat Express Corp. All Rights Reserved. |